Materials for the Extreme Working Conditions

In the oil&gas industry, the materials would always face extremely working conditions, such as high temperature, high pressure, corrosion, and high wear. Meanwhile even if in such a harsh working environment, the plastics are still demanded to keep high mechanical strength, great electrical insulation, very good dimensional stability, and other good properties. So you need not only excellent materials but also a supplier who understand the industry.

Keward has the abundant practical experience and a wealth of knowledge. We had cooperated with industry leaders like CNPC, CNOOC, and so on. Our engineers helped them to select materials, solve the problems and improve the design.

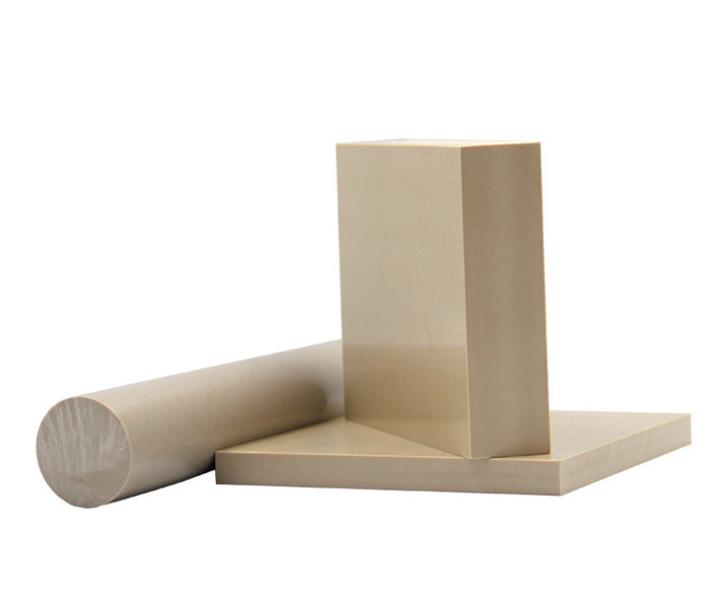

In the oil&gas industry, the materials like PEEK, PEEK GF30, PTFE, PA 6G are widely used to fit in different working conditions. Meanwhile, besides the usual rods and sheets, Keward also provides large size or customized-size tubes. These materials are always machined to seal support rings, electric insulation coats, valve seats, and other components to fit in each application. You can find the recommended materials and cases in the following content.

Solutions for Oil&Gas Industry

Keward offers many thermal stable materials which the highest continuous working temperature is up to 300℃ depending on applications. The most recommended materials are PEEK Virgin, PEEK GF30, and PI HI.

Excellent chemical resistance

The corrosive fluid usually exists in the downhole. PEEK Virgin, PEEK GF30, PTFE shows exceptional chemical resistance.

Electrical insulation

For the electrical logging equipment, electrical insulation under the condition of high temperature and high pressure(HTHP) is considered one of the main vital factors. PEEK VIrgin, PEEK GF30 is proven in such applications.

Thermal stable under HTHP

Even in the HTHP condition, compare to the PEEK Virgin, PEEK GF30 shows even better thermal stability.

Excellent wear resistance

In the open hole well, especially for the horizontal well, the equipment has to friction against the rock wall. PEEK GF30 is proven excellent wear resistance for this application.

Materials for Oil&Gas Industry

PEEK Virgin

PEEK virgin is an unfilled semi-crystalline high-performance plastic with high continuous temperature, good mechanical strength, excellent dimensional stability, and exceptional chemical resistance.

PEEK GF30

PEEK GF30 is a 30% glass fiber reinforced material based on PEEK virgin. Compared to PEEK virgin, the rigidity and wear resistance are improved, especially under the condition of high temperature and pressure.

PEEK Tubes

We use the method of extrusion or compression moulding to produce the PEEK virgin or PEEK modified tubes and rings. So the size range of the product is really wide and could be customized.

PTFE Virgin

PTFE virgin is one of the most widely used high-performance plastics. It exhibits exceptional chemical resistance, very good slide and wears properties, excellent electrically insulation, and other benefits.

Ultem Virgin

Ultem virgin has high mechanical strength, high rigidity, dimensional stability, and very good radiation resistance. It also has very good wave permeability and can be used in the telecom industry.

PPS GF40

PPS GF40 is a 40% glass fiber modified material based on PPS natural. For glass fiber reinforcement, it shows high rigidity, good wear resistance, great dimensional stability, and other benefits. Also could provide black color.

PA 6G

Nylon 6G is a casting material based on PA 6 virgin. Because of the casting process, large sized plastic can be provided.

PI Virgin

PI virgin is an unmodified polyimide that has high rigidity, low water absorption, good machinability, and very high continuous temperature.