Low Dissipation Factor, High Transmissivity and Stringent Anti Static Material Solution for Electronic Industry

For the electronic industry, engineers are always concerned about electrical properties such as dielectric strength, dissipation factor, dielectric constant, and etc. Especially for the electrical connector, people try their best to find out the plastic that has the lowest dissipation factor in the certain hertz.

Future more in the telecommunication industry, many high-performance engineering plastics are widely used as the specific radome. In this application, the transmissivity of the material is the vital factor, and materials’ weather resistance also should be considered as one of the main factors.

However for the semiconductor industry, especially for the testing process, the specific surface resistance of material determines the testing result. The testing process requires stringent anti-static material.

Keward provides an extensive range of plastics that has the properties of stable dissipation factor, low dielectric constant, high transmissivity, very good weather resistance, and stringent anti-static.

Solutions for Electronic Industry

Low dissipation factor materials

The dissipation factor determines the performance of the components. The lowest dissipation factor can be reached at 2.02. PEEK Virgin, PTFE Virgin, Ultem are widely used.

High transmissivity materials

Materials like PEEK Virgin and Ultem are always used as radome due to its high transmissivity, good weather resistance and good paint adhesion.

Anti static materials

The Acetal ESD can be used as the testing socket for the semiconductor testing process. If you need PEEK ESD please contact us too.

Insulation materials

Keward provides a wide range of electric insulation plastics. Contact us and describe your application, we will recommend you right material.

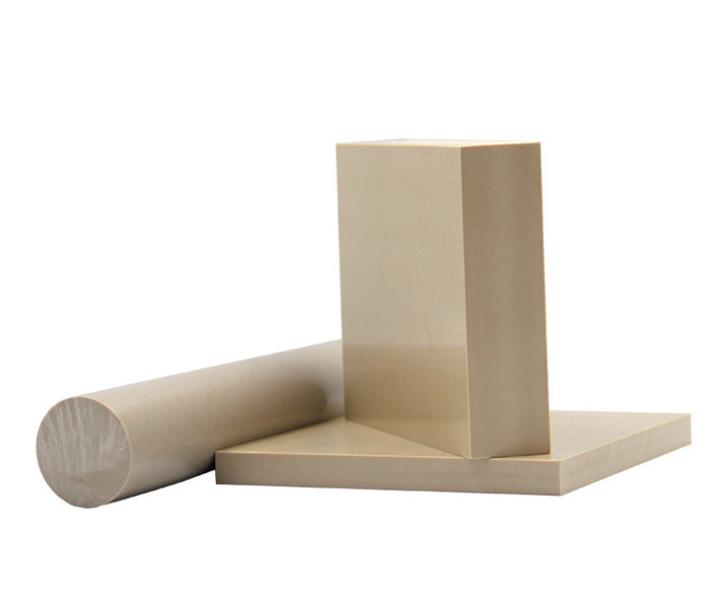

Materials for Electronic Industry

Ultem Virgin

Ultem virgin has high mechanical strength, high rigidity, dimensional stability, and very good radiation resistance. It also has very good wave permeability and can be used in the telecom industry.

PEEK Virgin

PEEK virgin is an unfilled semi-crystalline high-performance plastic with high continuous temperature, good mechanical strength, excellent dimensional stability, and exceptional chemical resistance.

PTFE Virgin

PTFE virgin is one of the most widely used high-performance plastics. It exhibits exceptional chemical resistance, very good slide and wears properties, excellent electrically insulation, and other benefits.

PEEK GF30

PEEK GF30 is a 30% glass fiber reinforced material based on PEEK virgin. Compared to PEEK virgin, the rigidity and wear resistance are improved, especially under the condition of high temperature and pressure.

Acetal ESD

Acetal ESD is a special material by adding an antistatic agent based on Acetal virgin. It keeps both the mechanical properties and good anti-static function.

PPS Virgin

PPS virgin is a high performance plastic with great benefits of high continuous temperature, good machinability, excellent dimensional stability and low water absorption. Black and natural color are available.

PPS GF40

PPS GF40 is a 40% glass fiber modified material based on PPS natural. For glass fiber reinforcement, it shows high rigidity, good wear resistance, great dimensional stability, and other benefits. Also could provide black color.