Plastic Solution for Mechanical Engineering

Traditionally, mechanical engineering likes to use steel or metal alloys in order to get the high mechanical strength and precision of the components. But the metal materials also have their own inevitable disadvantages, such as heavyweight, extra lubrication needed, no resistance under corrosive conditions, and so on.

So nowadays, high-performance engineering plastics are gradually replacing metal and the trend is becoming more and more popular. The plastic material has many benefits that the metal is incomparable, such as good chemical resistance, lightweight, electrical insulation, and etc.

Plastic is always an ideal solution for mechanical components like gears, seals, sliding elements, valve seats, and other applications.

Keward provides a wide range of high-performance engineering plastics and has extensive application experience. We could not only provide high-quality materials but also offer practical suggestions on materials selection, design, and machinability.

Solutions for Mechanical Engineering

Corrosion resistance

For corrosive working environments, metal materials may have some problems. But the plastics like PTFE, PEEK Virgin and others could cope with it.

Sliding optimized materials

The self-lubricating plastics with special additives could enhance the sliding properties and wear resistance. Such as Oil filled nylon, MC Nylon, PTFE, PEEK PVX, Acetal, etc.

Light weight

Many low-specific density materials are useful in aviation, moving applications in order to achieve weight limitation, higher operating speeds, and less energy consumption. Plastics like ABS Virgin, Acetal, and MC Nylon are recommended.

High mechanical strength

The materials which are reinforced by glass or carbon fiber always show better mechanical strength, and higher stiffness, and are more stable under the condition of high temperature and high pressure. Recommend plastic PEEK GF30, PEEK CF30, PPS GF40, Ultem 2300.

Impact resistance materials

Impact resistance plastics should have the property that components need to withstand frequent impacts without cracking. Recommend materials like ABS Virgin, PA 6, PC Virgin, and HDPE.

Materials for Mechanical Engineering

PA 6 Virgin

Nylon 6 is a good engineering plastic with the properties of good impact resistance, good machinability, good wear, and slide performance.

Acetal Virgin

Acetal virgin is a widely used material with great properties of high mechanical strength, good machinability, high rigidity and toughness. It can be used in many applications.

PEEK Virgin

PEEK virgin is an unfilled semi-crystalline high-performance plastic with high continuous temperature, good mechanical strength, excellent dimensional stability, and exceptional chemical resistance.

PTFE Virgin

PTFE virgin is one of the most widely used high-performance plastics. It exhibits exceptional chemical resistance, very good slide and wears properties, excellent electrically insulation, and other benefits.

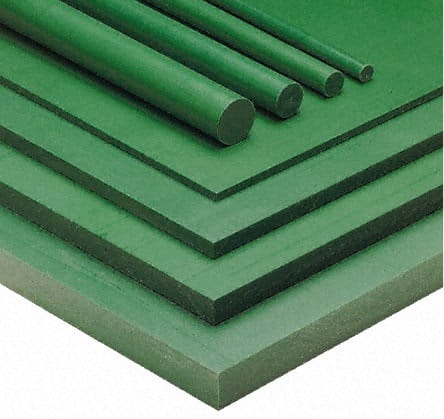

Oil Filled Nylon

The oil-filled nylon is a modified engineering plastic based on PA 6 by adding special oil lubricant. It is very suited for sliding and bearing applications.

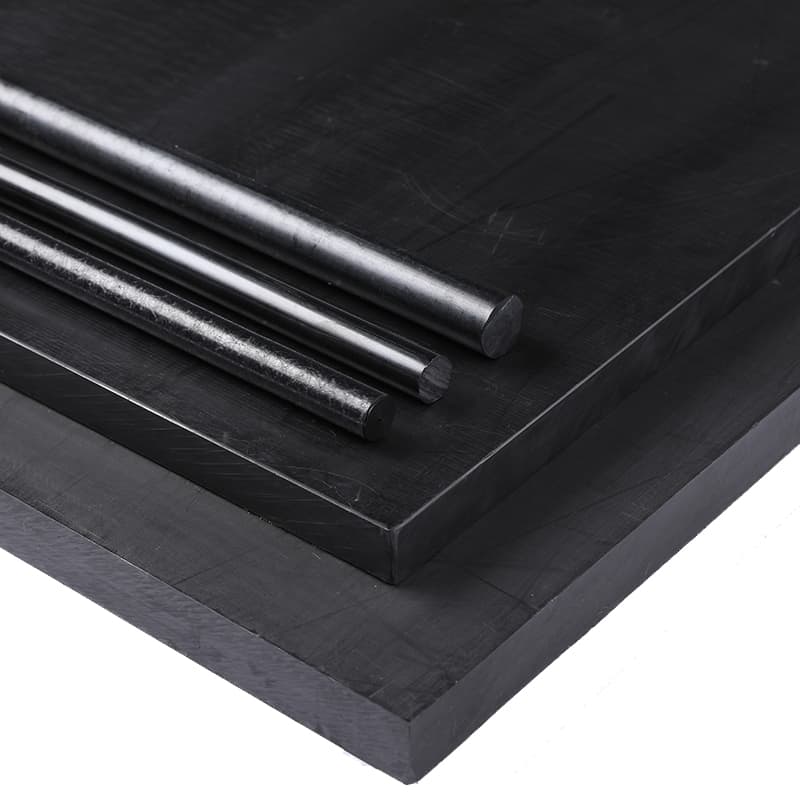

PPS Virgin

PPS virgin is a high performance plastic with great benefits of high continuous temperature, good machinability, excellent dimensional stability and low water absorption. Black and natural color are available.

PEEK PVX

PEEK PVX is a bearing grade PEEK plastic. It has excellent wear resistance and sliding performance by adding PTFE, graphite, and carbon fiber. PEEK pvx is an ideal material for any sliding situation.

Ultem Virgin

Ultem virgin has high mechanical strength, high rigidity, dimensional stability, and very good radiation resistance. It also has very good wave permeability and can be used in the telecom industry.